Your ERP Platform Cannot Do EDI

For companies working in the supply chain, EDI systems and ERP solutions are critical for doing business. On the front-end, EDI enables communication with trading partners and on the back end, the ERP is used as a system of record.

Today, integration technology has advanced significantly, enabling connected data streams between EDI and ERP solutions.

Recognizing the value of EDI software, many ERP companies have chosen to offer EDI services in an ERP package as a part of a greater platform.

But, EDI integration is inherently difficult as it requires the connection of a vast array of moving parts. When done correctly, complete EDI to ERP integration can give your supply chain business a huge boost in efficiency and visibility. When configured improperly, EDI to ERP integration becomes a rats nest of custom integrations that hinder the business.

Before we dive further into the value of EDI and ERP integration, let's first understand EDI ERP integration by defining each part.

What's EDI?

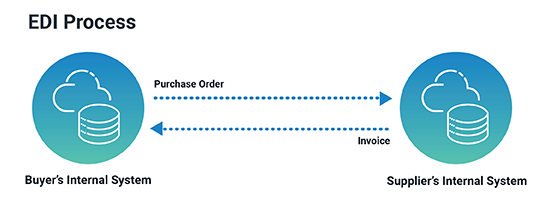

EDI is a computer-to-computer exchange of business documents in a standard electronic format between different business partners.

Below you can see how a basic EDI process works with two trading partners exchanging a Purchase Order and an invoice.

What is an ERP?

An ERP (Enterprise Resource Planning) is usually referred to as a category of business management software—typically a suite of integrated applications—that an organization can use to collect, store, manage and interpret data from many business activities. ERP systems track business resources including:

- Cash Raw

- Materials

- Production

- Capacity

ERP systems also track business commitments:

- Orders

- Purchase Orders

- Invoices

- Payroll

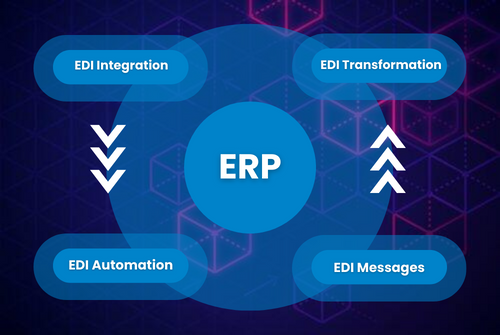

What is ERP and EDI integration?

EDI ERP integration is a process of enabling data to automatically flow between a business' front-end," EDI application, and its "back-end," ERP system. Automating the transmission and translation between EDI and ERP solutions removes the need for manual re-keying of messages, orders, or invoices and eliminates the possibility of user error.

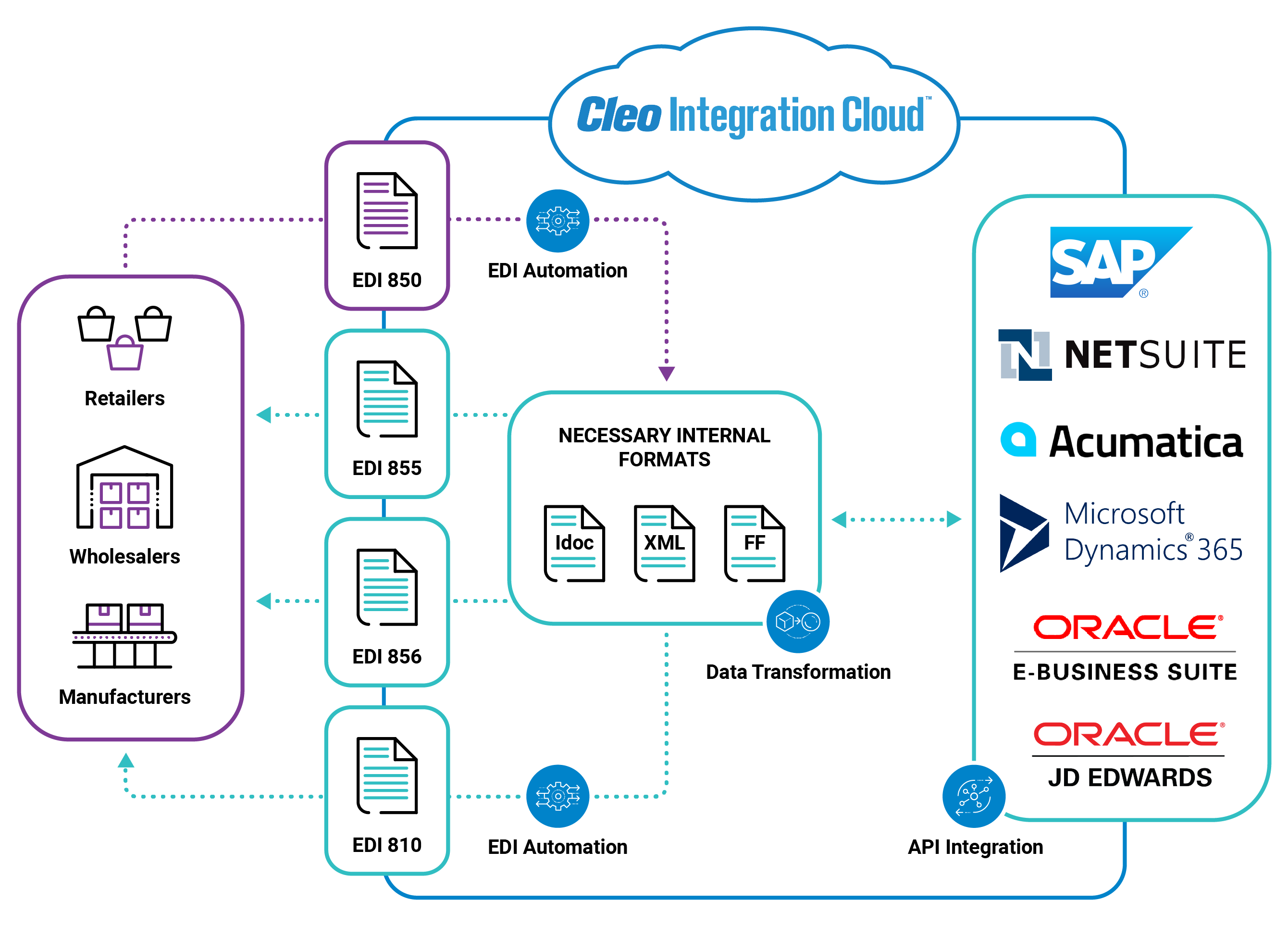

In the below diagram, you can visualize EDI to ERP integration.

- On the upper left-hand side, an inbound EDI 850 purchase order is received from a retail, wholesale, or manufacturing partner.

- That EDI 850 transaction is automatically tallied and then converted to an internal format (Idoc, XML,FF) to be ingested into an ERP on the righthand side (SAP, Netsuite, Acumatica, Dynamics 365, Oracle E-Business Suite, Oracle JD Edwards.

- Finally, the information that was previously contained in those EDI documents, now in the correct internal format, is pushed into the ERP solution on the right-hand side using an API connection.

It is no wonder then that EDI and ERP integration has continued to be prioritized by organizations in the supply chain world.

The Value of Automated ERP and EDI integration

Traditionally the relationship between EDI and ERP has been separated by the boundaries of each software solution. Each would manage its respective business process, but the two components could not integrate well.

Companies would either manually enter EDI data into their ERP solution or create a haphazard, custom integration to attempt to create a data flow between the two solutions.

Today that calculus has changed. Modern EDI systems offer a way of integrating with your ERP that is both seamless and transformative.

Creating ERP and EDI integration offers several advantages including:

- Improving data accuracy

- Increasing business cycle speed

- Enhancing supply chain visibility

Accurate data: Automating EDI ingestion and transformation into your ERP eliminates the need for manual data entry. As a rule, manual data entry will result in errors as data is erroneously entered. Even if 1% of orders are entered incorrectly, those misplaced values will create headaches for the entire organization. Creating an automated pipeline between EDI and ERP prevents mistakes from occurring in the first place.

Speed business processes: EDI and ERP integration allows your business to drastically reduce processing times. When you can automatically exchange EDI transactions with your trading partners in minutes instead of days, your organization can complete business cycles faster.

Visibility over trading partners: An automated EDI and ERP integration enables your business to spend more time focusing on increasing business. Because the data moving between EDI and ERP is accurate, automated, and easily accessed within your ERP, you can focus instead on how your EDI partners are affecting your entire business. No more chasing around missed orders or frantically searching for failed EDI transmissions.

The ERP/EDI Relationship

When the time comes for a company to undergo an EDI migration, often the decision becomes whether to use their ERP software for EDI or continue to use separate applications. No matter how an enterprise decides to transform its environment, it is important to understand the dangers of using a combined ERP solution.

An EDI upgrade is IT modernization at its very peak, but the reality is many of those projects have a very high failure rate. Up to 75% of all EDI migrations fail, according to industry analysts, often because businesses are unprepared for the complexity of the process and the EDI integration, which usually isn't a component of EDI solutions offered by ERPs.

Traditional ERP solutions like Epicor, IQMS, and Oracle offer patched-on EDI solutions that are intended to complement and integrate with their primary ERP components, but there is more to EDI than sending and receiving transactions. In truth, linking the EDI and ERP systems via an ERP vendor may end up exposing the organization to greater risk.

Here are 4 reasons why you should not combine your EDI and ERP solutions:

1. Risk to partner relationships

One of the key benefits of separating EDI and ERP software solutions is the ability to complete software infrastructure changes quicker. A well-oiled EDI provider can stand up partner connections in days rather than months, whereas bolt-on EDI solutions offered by ERPs do not offer the same kind of speed. This difference is because of focus.

Because ERPs are focused on improving their underlying product values such as their order management or product inventory components, there is less attention on front-end processes to improve EDI partner onboarding. Prioritizing work on ERP functions frequently comes at the cost of adding a critical EDI feature.

Trading partners are waiting! Of course, the ERP software vendor hoping to sell his EDI module will wave off such concerns by referencing the fact that EDI services in the ERP platform are "fully integrated." That response fails to acknowledge where the real EDI migration and integration efforts take place—setting up trading partners and testing the interchanges.

EDI systems with modern design and new-age EDI mapping tools will make EDI onboarding more efficient by reducing the effort required to set up and manage trading partners.

An EDI solution streamlines changes to custom code necessary to support new trading partners' ends. It offers a faster turnaround of change requests, often translating into increased revenue and reduced operating costs. Additionally, EDI vendors have experience connecting to thousands of trading partners and often have pre-packaged EDI maps ready to quickly deploy to set up a new connection. The same cannot be said for ERPs.

Evaluating and selecting software, both for EDI and ERPs often happens at levels above the operational EDI team. Adrenaline-powered IT managers must recognize the greatly increased risk that comes with deploying haphazard EDI solutions on top of an ERP.

2. ERP Limitations

Trying to install a new EDI system from an ERP vendor can double the risk of system failure. The most modernized platforms deliver layers of EDI visibility that cannot be equaled by an ERP application. EDI vendors structure their platform around delivering real-time status updates, precise error resolution, and exact tracking of business processes.

An ERP vendor without a proven EDI interface cannot compete and often adds multiple elements of risk to schedule, cost, scope, and quality.

ERP systems are structured as destinations and repositories for data. By nature, they have functional strengths and weaknesses. A good ERP application with "integrated" EDI capabilities may limit your ability to respond quickly to new standards and customer requirements. Users lose options within tightly coupled systems that lack flexibility or agility. Oftentimes the only "solution" to working around a brittle EDI solution offered by an ERP is to spend unplanned dollars writing custom code outside of the EDI component to achieve the desired business result.

ERP limitations can result in businesses shouldering the high costs of ongoing maintenance, a.k.a. "technical debt."

On the other hand, EDI systems with modern visibility tools give your business the ability to perform complex EDI alterations within a single, well-defined platform.

3. Integration stretches beyond EDI and ERPs

Although a significant portion of external data will be ingested into a given organization's ERP, there are several other applications that can also require integration, including your TMS, WMS, CRM, and/or eCommerce solutions.

For supply chain companies, TMS platforms are critical in helping plan, execute, and optimize the incoming and outcoming flow of physical goods. These systems also make sure the shipment is EDI compliant and that proper documentation is available. It should be noted that the TMS often sit between ERPs and external applications like EDI, processing orders into shipments before sending information on to the ERP.

WMS systems play another important function in allowing companies to execute processes like tracking products and manufacturing resources. WMS solutions are invaluable to warehouse functionality and distribution centers, giving companies real-time information on inventory levels. For 3PL companies, the importance of WMS integration cannot be understated. EDI data flows need to pass through both WMS and ERP for complete integration visibility.

Next, your CRM manages customer data, purchases, and contact information. Connecting your CRM and ERP enables an automated, single source of information that eliminates data duplication. For sales and marketing teams, the value of this integration is unparalleled.

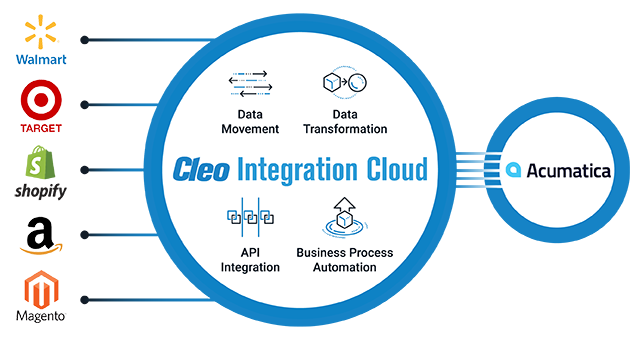

Finally, eCommerce has conquered the world. The Amazon effect has sent shock waves through the supply chain. For logistics companies, eCommerce has skyrocketed demand for final mile logistics and increased demand for visibility in shipping. For manufacturers, many are considering eliminating the middleman and starting to ship directly to consumers. Lastly, wholesalers are using eCommerce to expand into new distribution channels, diversify products and prioritize transparency. As your supply chain company adopts an eCommerce strategy, that initiative will involve the adoption of applications like Amazon, Magento, and Shopify. Integrating your EDI, ERP, and eCommerce solutions will be the next frontier for application integration.

In the below diagram you can see a wide variety of external connections to an ERP. Not only do you have trading partners like Walmart and Target, but also data from eCommerce applications. All of those connections have to be integrated with the Acumatica ERP on the righthand side.

In truth, there is tremendous value to connecting all your applications with your front-end processes, not just your EDI.

But integration is far more than a simple connection between applications. The EDI implementation infrastructure required to set up an EDI to TMS to ERP can be extensive and require in-depth EDI and API knowledge. If your business requires integration beyond EDI and ERP connection, most will ERP will not have 'out of the box' connectors available or the experience to build a custom integration. If your integration stretches to multiple trading partners and varied applications, a true EDI integration platform is superior to an ERP vendor that acquired an EDI tool.

4. Modern EDI Systems are already made to integrate with your ERP

After establishing your EDI and ERP integration requirements, the truth of EDI integration becomes clear. The most efficient and lowest cost will be the result of allowing each software system to perform the function it was intended to do.

EDI was created to manage front-end trading partner relationships.

ERPs were made to manage back-end processes as universal systems of records.

Because each solution has a fundamentally different purpose, it is in every company's best interest to keep them separate.

The very best EDI technology integrates with ERP systems and can handle inbound and outbound transactions. Whether it is a flexible setup or run-time environment, companies must have a clear understanding of how the EDI interfaces are maintained and what is the potential negative impact of putting back-end systems in charge of front-end processes.

Modern EDI solutions offer levels of B2B integration expertise and platform capabilities that cannot be matched by an ERP bolting on a simple EDI tool.

If your business values real-time supply chain visibility, automated ingestion of EDI documents to your ERP, and faster trading partner onboarding, then an ERP cannot replace your EDI solution.

Modernize Your EDI System and then Connect to Your ERP

EDI is integral to the supply chain and remains the standard. Therefore, modern companies need a modern EDI solution to conduct business. Organizations that do decide to replace a legacy system EDI must ensure that they can quickly and easily make the move without disrupting existing business workflows and processes, and enterprise integration technology enables a successful data migration.

Modernizing your EDI using an advanced cloud EDI platform positions your company to take on new business and respond quickly to customer and trading partner requests. The last thing you need is to disrupt your data flow and business processes because your ERP's cheap EDI environment isn't up to date.

Cleo Integration Cloud elevates your EDI integration processes and streamlines your B2B communications. Cleo Integration Cloud helps automate your EDI processes to connect, transform, and route your EDI and non-EDI transactions through your ecosystem without piling on the custom code.

Discover the benefits of using Cleo Integration Cloud for EDI integration by watching some short demo videos:

About Cleo