How Manufacturers Can Achieve Better 3PL Integration Control

Third-party logistics companies (3PLs) offer logistics services to manufacturers that wish to outsource the responsibilities. They can provide a wide range of services, including:

● Inventory management

● Warehousing

● Shipping coordination

● Order fulfillment

What Is 3PL Integration?

3PL integration is to establish seamless communication and collaboration between the 3PL and its customers or partners. 3PL integration solutions use automation to improve the efficiency of the load tender-to-invoice processes across trading partners, TMS/WMS/ERP applications, and eCommerce fulfillment services. They provide real-time visibility into inventory across warehouses and business processes and allow products to be delivered more quickly.

Why Do Brand Manufacturers Utilize 3PLs?

Manufacturers may utilize 3PLs for a variety of reasons, including:

● Improved fulfillment performance

● Quickly scale depending on demand

● Access to a team of logistics experts

● Allows manufacturers to focus on their strong-suit

● Cost-savings

● Expand into new/international markets

● Faster delivery times

Complexities of 3PL Integration

3PL integration solutions are advantageous but can be complex to get right. This is because manufacturers and 3PL companies need to set up integrations that allow for real-time data sharing, which is where EDI software comes into play.

3PL EDI integration improves efficiency by automating business processes, manual tasks, and processes, and allowing for greater supply chain visibility. Manufacturers can also integrate with other trading partners, such as suppliers and retailers, to improve the efficiency of other processes as well. Therefore, manufacturers need widespread EDI protocol support so they can connect and conduct business with as many trading partners as possible. Otherwise, they will limit the number of trading partners they can work with since each company has its own EDI requirements.

It is also common for manufacturers to work with multiple 3PLs, which means they have to create and manage various integration environments. This is especially difficult when an integration solution does not allow users to manage all connections from one, centralized location. Some solutions, like Cleo Integration Cloud (CIC) though, let users manage all connections out of one central location, while also giving users the ability to create custom dashboards.

Manufacturers must be able to communicate with their 3PL providers and ensure that their order process is fully automated. EDI on a centralized integration platform will then deliver every EDI transaction required, from advanced shipping notices to purchase orders and acknowledgments. It is difficult enough for manufacturers to manage manual connection methods. However, with a reliable partner on their side who can provide modernized EDI, manufacturing companies can outperform their competitors.

Why Is 3PL Integration so Challenging?

There are a few likely scenarios that make 3PL integration challenging, including no standardization, integration avoidance, and a lack of expertise.

No Standardization

In the majority of EDI integration relationships, one party decides on the format and requirements for EDI transactions, while the other follows the demands. When it comes to 3PLs and manufacturing, there is little standardization in this area, meaning that neither party necessarily wants or knows how to lead this process. This can leave both parties in a state of uncertainty.

Lack of Expertise

3PLs do not always have the experience to create EDI integrations with manufacturers. Part of the reason for this is that 3PLs tend to be smaller businesses that do not have the internal expertise to onboard, test, deploy, and maintain integrations. This leads to errors and confusion while the 3PL and manufacturer try to get their integrations up and running.

Integration Workarounds

In an effort to avoid EDI integrations, 3PLs are sometimes granted access to the manufacturer's warehousing software. The 3PL can then pick and pack from the manufacturer's warehousing software to avoid having to set up integrations. However, this is not a good long-term solution as it is not scalable. For example, if the 3PL is doing this for 20 customers, they cannot specialize in each companies' system and learn the intricacies of each. Therefore, the process becomes inefficient and error-prone.

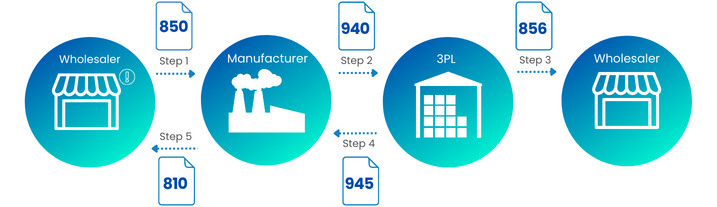

Uncomplicate Every Transaction

This above visual is the 3PL EDI process between the manufacturer, 3PL, and the wholesaler. Different industries utilize different transaction types. Cleo supports every document type for 3PLs. The most common EDI transactions between 3PLs and manufacturers are:

856—Ship Notice Mandate

The EDI 856 transaction, also known as an EDI advance shipping notice or EDI ASN, is a critical and widely used document that notifies the receiving party of a shipment, specifically describing the contents of a shipment. The document is sent preceding a shipment's arrival. Many major retailers require it to be sent within a certain time frame before the product arrives at a given distribution center or store.

943—Warehouse Stock Transfer Shipment Advice

The EDI 943 warehouse stock transfer shipment advice is an advance ship notice to a remote warehouse indicating the transfer shipment has been made from the manufacturer. EDI 943 is also utilized by manufacturers to authorize a warehouse to accept a return from a customer.

944—Warehouse Stock Transfer Receipt Advice

The EDI 944 warehouse stock transfer receipt advice acknowledges to a manufacturer that its transfer shipment has been received.

940—Warehouse Shipping Order

The EDI 940 warehouse shipping order instructs remote warehouses to ship orders. It is most often used by a seller, wholesaler, or manufacturer, to authorize a warehouse to send a shipment to a buyer, like a retailer.

In short, the EDI 940 more or less informs the warehouse on what to ship, when to ship, and how much to ship.

945—Warehouse Shipping Advice

The EDI 945 warehouse shipping advice transaction replaces a paper invoice and gives confirmation of shipment. An EDI 945 transaction is utilized by a warehouse so it can notify a trading partner when a shipment is made.

850—Purchase Order

An EDI 850 purchase order is used to initiate an order with a vendor and includes order information about the items being ordered, like item number, quantity, and price. It helps streamline the buying process, allowing vendors to run their businesses more efficiently and buyers to get their goods in a time-efficient manner. Trading partners can safely share sensitive data like pricing because EDI transactions are encrypted in transit. EDI 850s are typically the first step in the purchase order process.

810—Invoice

The EDI 810 invoice confirms an order has been shipped and can be used across various order types. EDI 810s are typically used by companies to automate the process of billing and payment for goods or services. The 810 is sent in response to an EDI 850 Purchase Order as a request for payment once the order has been shipped or service has been provided.

What Are the Relationships Between These Different EDI Transaction Types?

Below are examples of how EDI transactions are used in a purchase order and stock transfer.

Purchase Order

Step 1

The process starts with a retailer sending a manufacturer an EDI 850 purchase order.

Step 2

To fulfill the order, the manufacturer sends a 3PL a 940 warehouse shipping order, informing the 3PL what to ship, when to ship, and how much to ship.

Step 3

The 3PL fulfills the order and sends an 856 ship notice mandate to the retailer. This communicates that the shipment left the warehouse and is in transit.

Step 4

The 3PL sends a 945 warehouse shipping advice to the manufacturer that the shipment left the warehouse and is in transit.

Step 5

The manufacturer sends an 810 invoice to the retailer after receiving confirmation that the shipment is in transit.

Stock Transfer

Step 1

The manufacturer sends a 943 warehouse stock transfer shipment advice to the 3PL that notifies them that a shipment is headed to their warehouse and it also includes delivery information.

Step 2

After receiving the shipment, the 3PL sends the manufacturer a 944 warehouse stock transfer receipt advice, informing the manufacturer that the shipment was delivered. The 944 can also include revisions to the 943, usually if the delivered shipment contains damaged or missing goods.

How to Manage Your 3PL EDI Integrations as Effectively as Possible

Some of the most frequent issues that manufacturers tend to experience with 3PL EDI integrations are due to outdated/legacy technology, manual processes, and unscalable solutions.

To reap the benefits of 3PL EDI integrations and manage the connections as effectively as possible, companies can first implement an EDI software solution with widespread protocol support. Then, designate one party to spearhead the integration (either the manufacturer or 3PL). The 3PL tends to be a good leader for this because their operations remain the same, no matter which manufacturer they are working with. Therefore, the 3PL can create the integration requirements and the manufacturer can create integrations that align with the mandates.

From here, it is in a company's best interest, whether a manufacturer or a 3PL, to have a designated team member(s) monitoring all EDI transactions and integrations. This helps companies avoid missed SLAs, address errors as soon as they occur, and optimize processes, all of which help increase efficiency, improve customer relationships, and avoid supply chain disruptions.

Benefits of 3PL integration

• Eliminate manual work

• Spend less on faxes and paper

• With more current information, make wiser decisions

• Improve your inventory and margin management

• Free up staff for higher-value projects

What Does Better Integration Control Look Like?

As disruption continues to plague supply chains, companies are looking for ways to mitigate the impact it has on operations. One way is through gaining integration control. Integrations control ushers in a host of benefits, including faster error resolutions, accelerated time to revenue, faster onboarding, and real-time data.

Improved Error Resolution

Supply chain errors are one of the biggest reasons for disruptions. With a solid integration solution, companies can be notified as soon as an error occurs, whether in-platform or via email or text.

Furthermore, the notification should inform users exactly where the error is happening. This way users do not spend valuable time hunting down where the error is stemming from, but rather can hop right into fixing the issue. Thus, minimizing the chance the error disrupts the supply chain.

Faster Onboarding

Onboarding is one area that customers are consistently dissatisfied with. According to Cleo's 2023 Ecosystem Integration Report , 16% of survey respondents said it takes more than one month to onboard new trading partners. Finding an EDI integration solution that is capable of fast onboarding is critical, as it accelerates time-to-revenue since companies can start working with trading partners more quickly.

Real-Time Data and Visibility

Access to real-time data is crucial for companies to understand their businesses and operate at peak performance. The top integration solutions provide companies with real-time data in one, centralized location.

This is possible because the EDI integration solution shares information in real-time with all platforms, systems, and trading partners it is connected to. This shared, real-time information is then presented to users. The leading solutions will show this data to users in a customizable dashboard, allowing users to select which data they want to be shown. Companies can use this data to optimize processes and influence decision-making.

The Best EDI Software Solution for 3PL Integration Is Cleo Integration Cloud

The leading ecosystem and EDI integration solution on the market is Cleo Integration Cloud (CIC). CIC brings control, visibility, and flexibility to the forefront, enabling companies to operate at peak productivity while governing with confidence.

With fast onboarding, real-time data, error notifications, a variety of service options, and prebuilt maps and templates, companies and their trading partners quickly reap the benefits of CIC.

Additionally, companies can consolidate EDI software solutions by migrating to CIC. Our vast protocol support and widespread integration capabilities empower companies to connect with nearly any partner using only one, all-encompassing solution; CIC.

If you have any questions or want to learn more about Cleo, our EDI software offerings, managed services, or ecosystem integration in general, contact us at sales@cleo.com or +1.815.282.7695. You can also explore some of our educational resources on our content hub.

By integrating with our platform, businesses can reduce errors, improve data accuracy, and increase overall efficiency, resulting in improved customer satisfaction and increased profitability.

About Cleo