Blog: 2 Key Supply Chain Capabilities for Companies Affected by Steel, Aluminum Tariffs

For years, manufacturers across industries have built their products using materials purchased all over the world. But what stands to happen to these companies after President Donald Trump imposed higher tariffs on imported steel and aluminum?

The ripple effect of these protectionist measures remains relatively uncertain, but the reality is that U.S. companies are facing higher costs to import steel and aluminum from outside the U.S. It also means foreign countries could retaliate by increasing tariffs on U.S. imports, triggering a trade war that would ultimately cost consumers.

So how can organizations that are heavily dependent on the supply chain adjust to these tariffs?

Companies could chalk it up to the cost of doing business and simply pass these added costs onto their own customers. But agile, proactive businesses will look for ways to limit how much these tariffs will affect their customers and their own bottom line.

Sourcing New Partners

As many as 53 percent of companies are highly or critically dependent on suppliers, according to Deloitte, which means these tariffs might lead companies to take measures to source new domestic suppliers. But to do so quickly, companies looking to mitigate the added cost of doing business need rapid onboarding capabilities that allow for quickly adaptive change to its network of suppliers.

When these tariffs take full effect, companies that are highly reliable on suppliers are going to need to onboard new partners quicker than ever.

But what does onboarding entail? It involves configuring partner profiles and connections to securely exchange order, invoicing, shipping, and payment data (among other things). And that means companies must capably support:

- A variety of secure data movement protocols to connect to and communicate with a new partner

- Moving EDI or non-EDI data, which may include integrating ERP, OMS, TMS, and WMS applications

- Transformation capabilities to transform data into formats a new partner can use, whether they are EDI, XML, flat files, or others.

Bringing on a new partner isn’t a simple process, but it can be simplified using modern B2B integration technology that takes the manual effort out of such integration projects. Companies that can support any partner or internal integration requirements without custom code will be better positioned to automate the onboarding process. In the end, in successfully onboarding a new partner faster, these organizations can limit disruption to the sourcing and manufacturing process.

The Need for Better Supply Chain Visibility

Additionally, what about those companies that just don’t know whether such tariff increases are going to affect their business?

Supply chain visibility is absolutely critical, as it speaks to the availability and accuracy of data that represents the goods, services, and operational aspects of the supply chain. But according to the 2017 Business Continuity Institute report, 69 percent of companies do not have full visibility over their supply chains.

Blind spots in the supply chain can signal an area where cost optimization is not a factor, or even where increasing costs at a sourcing level aren’t accounted for. There’s a very good chance, then, that organizations importing steel and aluminum from overseas will face higher supply costs without knowing about it until much further down the road.

The need to be proactive instead of reactive is tantamount to success within a global supply chain ecosystem, and that starts and ends with increased visibility. Companies gain such visibility through an integrated IT infrastructure that includes pricing, inventory, sourcing, and other workflows so it delivers an entire view of its business.

Integration and Future-Proofing Your Business

In today’s world, companies must evolve and adapt quickly, and it’s no longer feasible for enterprises to sit around and react. The strength of the supply chain comes down to how quickly businesses can adapt to change, especially when it comes to sourcing the raw materials required to produce goods and services.

Modern organizations need to become proactive and get ahead of the competition, and that’s more evident than ever with these tariff increases. Legacy systems and custom coding cannot support onboarding new customers in a timely and effective fashion, and such disparate technologies silo the critical data flows and hinder visibility into daily business processes.

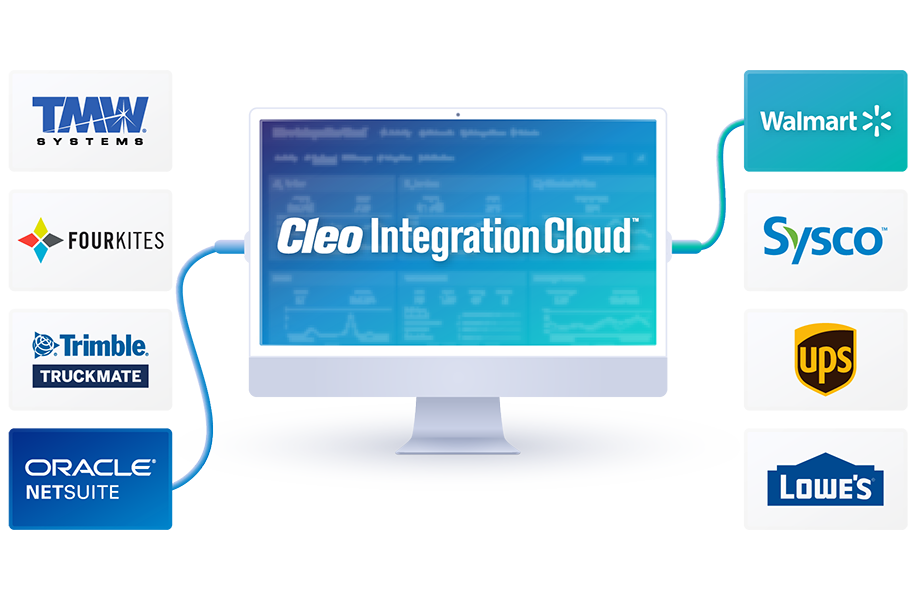

World-class supply chains have these onboarding and visibility capabilities built in. By leveraging a scalable infrastructure that supports cloud, B2B, and application integration that improves partner communications and increases transparency for the data flowing throughout dynamic ecosystems, these supply chain savants reduce the complexity and cost of partner onboarding and enables holistic views into the data flows that power your business.

While these tariffs certainly are a potential cause for concern, the fact remains that change is always present. Organizations might not be able to control protectionist-type measures that will affect the cost of doing business, but they can control the technology that powers their supply chain so they’re able to adapt to changing market forces and better serve customers.

About Cleo

Watch a Demo

Comprehensive Guide to Gaining B2B Control

Duraflame Case Study