Understanding the Purchase Order Process - Everything You Need to Know

In today's interconnected global workforce, a sluggish purchase order process can severely impede your business operations. The use of manual purchase order processing and outdated systems can be counterproductive, creating more problems than solutions. Depending on a manual purchase order process involving emails and spreadsheets is akin to having a bank account without access to ATMs.

A compelling solution to tackle this challenge is by embracing procurement automation. The digitalization of processes has the remarkable ability to transform cumbersome procedures into seamless operations. Still uncertain about the benefits? Explore our complimentary ebook that delves into the significance of automating procurement.

But before we dive into the details of an effective procurement system for successful PO management, let's examine the current state of purchase order management and identify its significant shortcomings.

What Is the Purchase Order Process in Detail?

In this age of technology, it's prudent to leverage a cloud-based solution such as Cleo for managing purchase orders. This can greatly assist in monitoring the entire lifecycle of purchase orders. However, before delving further into a procurement system designed for effective purchase order management, let's first examine the existing state of purchase order management and identify its primary shortcomings.

The purchase order process includes all the steps it takes for a B2B customer to buy a product or service. The process starts with a customer sending a purchase order to a supplier and ends when the customer sends the supplier payment for the order.

An efficient purchase order process helps customers receive the goods it orders faster, as well as allows customers to conduct business with larger, more established buyers. However, traditional purchase order processes rely on humans to facilitate communication between the customer and supplier, as well as to carry out each step of the purchase order process. Human intervention often delays the process since humans take breaks, make errors, and work slower compared to newer technology solutions that are available. Companies can combat the drawbacks of the traditional purchase order process by implementing a modern EDI solution which we will cover later on.

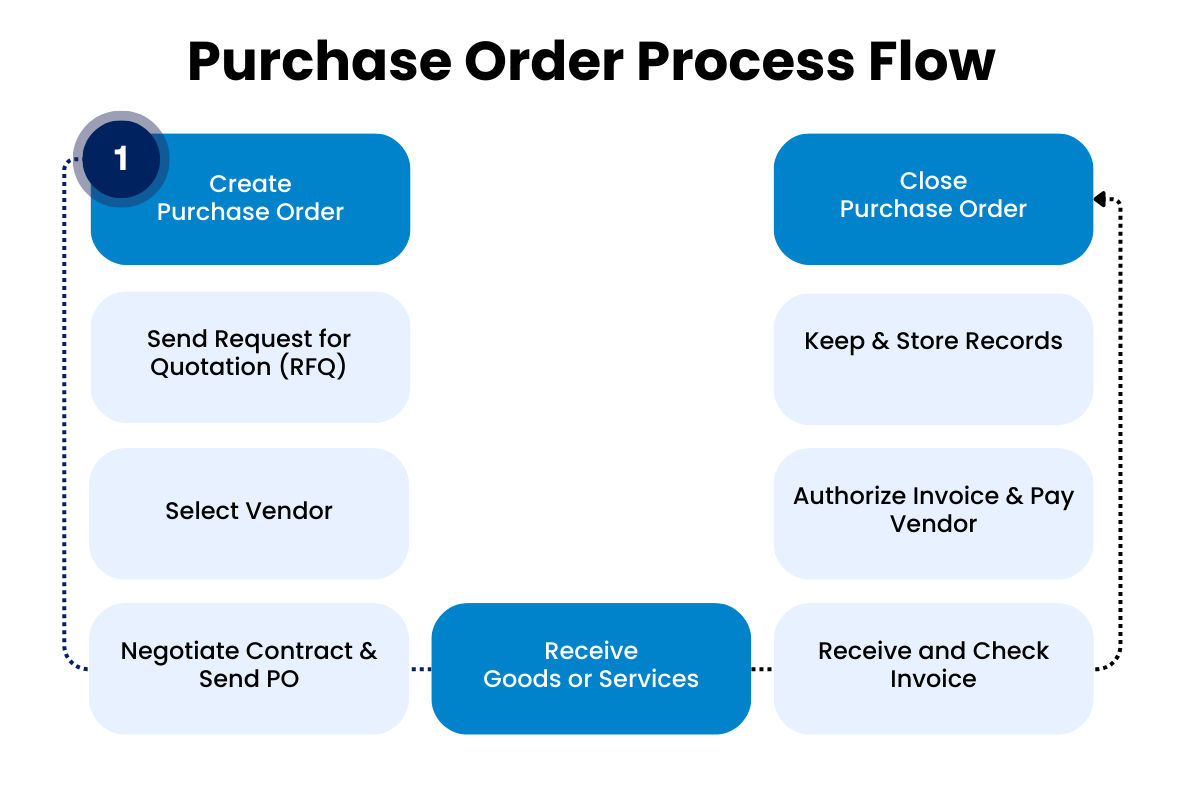

Overview of the Purchase Order Process Flow

The purchase order process involves multiple compliance checks and approval/input tasks to ensure prompt processing. Here are the most common steps in the purchase order process:

- Initiate a purchase order

- Request quotations from multiple suppliers (RFQ)

- Evaluate and choose a supplier

- Negotiate terms and issue the purchase order

- Receive goods or services

- Verify and reconcile invoices (3-Way Matching)

- Approve invoices and settle with the supplier

- Maintain records

- Close the purchase order process

The most common steps of the purchase order process are explained in more context and detail below.

- Initiate a purchase order: Begin the procurement process by creating an official request for goods or services.

- Request quotations from multiple suppliers (RFQ): Solicit competitive price and service proposals from various suppliers to make an informed choice.

- Evaluate and choose a supplier: Assess supplier bids and select the most suitable one based on criteria such as quality, price, and reliability.

- Negotiate terms and issue the purchase order: Finalize contract details and issue the purchase order to the chosen supplier, formalizing the agreement.

- Receive goods or services: Take delivery of the ordered goods or services in accordance with the purchase order.

- Verify and reconcile invoices: Match received goods or services with the purchase order and invoice to ensure accuracy and compliance.

- Approve invoices and settle with the supplier: Review and approve supplier invoices, then arrange for payment according to the agreed terms.

- Maintain records: Keep comprehensive records of all purchase order-related documents and transactions for future reference and compliance.

- Close the purchase order process: Conclude the purchase order process, ensuring all tasks are completed, and records are updated as needed.

Common Issues With Legacy (Manual) Purchase Order Processes

Legacy purchase order processes have remained largely unchanged since their advent. However, advancements in the fulfillment space now highlight the shortcomings of legacy purchase order processes.

Common issues with legacy purchase order processes include:

- Human intervention that results in errors and delays

- Slower overall processing times

- Siloed systems, applications, and data with poor visibility

- Complex, custom-coded solutions that require consistent maintenance

- Inability to quickly scale based on market demand

- Lack of support for the various document and protocol requirements mandated by each supplier

- Relying on separate backend systems including ERP, CRM, and TMS to get an order fulfilled

- Different systems requiring certain document types and formats such as iDOC, EDI, EDIFACT, and pdf

Main Downfalls of Manual Purchase Order Processes

- Diminish the productivity and efficiency of vital resources

- Result in significantly longer lead times for order processing and receipt of shipments

- Introduce intricacies and inconsistencies into the P2P workflow

- Affect key performance indicators (KPIs), including days payable outstanding (DPO)

Digitize Your Purchase Order Processes with Trading Partners Through a Web-based Portal

Effectively handling procurement procedures across various communication channels like email, phone, and fax within a disconnected supplier network presents a substantial hurdle. The need for manual intervention demands considerable resources, resulting in escalated expenses, higher instances of exceptions, elevated security vulnerabilities, and a diversion of attention from critical strategic endeavors. The sluggish, manual progression of purchase-to-pay (P2P) documentation cycles can result in inventory complications, disruptions in production, and downstream fulfillment issues.

To surmount this challenge, it is imperative to establish the capability to centralize, standardize, and automate all aspects of orders, purchase order acknowledgments, advance shipping notices, and invoices throughout the entire supplier ecosystem.

Customers can circumnavigate this human intervention by implementing a modern purchase order process. EDI is the digital transfer of business documents between trading partners in a standard electronic format. This process allows buyers and suppliers to send and receive information about orders, transactions, and messages, in a standardized, digital format.

Most importantly, this entire purchase order process can be fully automated for buyers. So from sending a purchase order to sending payment, no human intervention is required, removing the need for faxing, emails, and phone calls.

Benefits of innovative cloud solutions for procurement include:

- Improved efficiency and processing

- Minimal manual tasks due to automation technology

- Fewer errors and missed SLAs

- Increase in customer satisfaction and retention rates

- Real-time data collection across integrated system

- End-to-end transaction visibility

- Scalability

- Widespread integration and protocol support

To start, the buyer creates the order in their ERP or alternate purchasing system. Then, the order is converted into an EDI format and sent directly to the trading partner through the Internet (via an EDI AS2 provider or Value-Added Network).

Purchase Order Process Flow (with EDI)

A typical EDI purchase order process harnessing EDI technology involves the following transactions:

1. 850 Purchase Order

The customer sends the supplier an 850 Purchase Order to request a purchase. This is typically the first step in the ordering process, as it contains vital details about the requested purchase, including purchase order number and date, seller contact information, item details, delivery information, payment terms, etc.

2. 855 Purchase Order Acknowledgement

The supplier sends the customer an 855 Purchase Order Acknowledgement to notify the customer that an order has been both received and processed. It also informs the customer if the purchase order was accepted or rejected, or if alterations to the purchase order are required. The 855 contains information such as the date of the order, product information, delivery information, and any discrepancies that must be corrected.

3. 856 Advanced Shipping Notice (ASN)

The supplier sends the customer an 856 Advanced Shipping Notice before the shipment arrives at the customer's facility. This document provides shipment details such as shipping and delivery date, delivery location details, shipment tracking information, and item description.

4. 810 Invoice

The supplier sends the customer an 810 Invoice as a request for payment once the order has been shipped and delivered. The 810 includes information including invoice number and date, details about the order, acceptable methods of payment, and the total amount due.

5. 820 Payment Order / Order Remittance Advice

The customer sends the supplier an 820 Payment Order to confirm payment details, inform the supplier of any changes to the payment amount, and serve as a payment intent statement. The 820 is typically sent concurrently with the actual payment via an electronic funds transfer.

6. 977 Functional Acknowledgment

The supplier sends the customer a 977 Functional Acknowledgement to inform the customer that the supplier received the 820 and payment.

Best Practices for an Efficient Purchase Order Process

To further enhance the efficiency of a modern purchase order process, your business can take the following steps:

- Train employees who deal with the purchase order process so they fully comprehend all the steps and procedures to complete the purchase cycle.

- Build a continually updated database of preferred suppliers that offer reliable products, pricing, and services.

- Create and maintain positive trading partner relationships so the purchase order process flows smoothly and issues are resolved swiftly.

- Centralize purchase information so all relevant users can easily access it.

- Create master agreements with frequently used suppliers that outline pricing, terms, and conditions, etc., in an effort to minimize touchpoints.

Bringing Speed and Automation to Your Purchase Order Process

CIC PAVE serves as a modular extension of Cleo Integration Cloud (CIC), which is Cleo's primary ecosystem integration platform. CIC is specifically designed to facilitate the creation, implementation, management, and enhancement of essential purchase order processes. It elevates the integration of procure-to-pay (P2P) processes to a higher level, enabling you to seamlessly connect and integrate supplier interactions across your external business network, all the way to your ERP system, achieving comprehensive end-to-end process automation.

Businesses can achieve more efficient purchase order processing by harnessing automation. EDI purchase order automation will speed up the purchase order process by removing the reliance on humans to perform each step in the cycle. Therefore, human-made errors are eliminated, as well as the delays in response times. This allows buyers to operate their purchase order process 24/7—so they can acquire the goods and services they need more quickly.

Take Advantage of a Fully Integrated Purchase Order Process

Not only does a fully integrated purchase order process result in a quicker overall purchase cycle, but it also provides businesses with greater control, visibility, and insight. This is because cutting-edge integration solutions allow organizations to manage and monitor the process through a centralized location, such as a dashboard.

When viewing the dashboard, users should be able to dig down into each EDI code to gather necessary information, as well as be notified of any errors that are occurring in the purchase order process and precisely where they stem from. Users can also use the dashboard to view and analyze key metrics from all the integrated systems in their digital ecosystem. Therefore, they can quickly and easily access all pertinent findings in one, easy-to-navigate location, instead of having to log in to each individual system and manually pull the metrics. These in-depth findings can then be used to assess performance and optimize processes.

Questions or Issues in Your Purchase Order Process?

Cleo offers innovative purchase order process solutions that constantly adapt to the evolving needs of our customers. Built to drive efficiency and streamline communication between organizations, Cleo is focused on improving and optimizing your critical revenue-generating business processes.

If you have questions about what was covered in this blog, whether it's about purchase order processing in general, or Cleo's products and services, contact us at sales@cleo.com or +1.815.282.7695. Lastly, you can explore additional educational resources through our resource library.

About Cleo