How to Keep Supply Chain Innovation Moving Forward Amidst Recent Disruptions

Supply chain innovation is essential but not always easy to achieve. Modernizing the supply chain systems that power both freight companies and raw material suppliers can feel as slow as turning a container ship around.

Because of the current tumultuous world we live in, supply chain managers and vendors have no choice but to innovate in order to build supply chain resilience.

Supply Chain Outlook: Continued Disruption

When the pandemic caused massive disruptions to global supply chains in 2020, most assumed that manufacturing and distribution would return to normal once demand evened out. Yet, with the pandemic's shifts in demand behind us, supply chain disruptions remain.

Increasingly common factors that can disturb a supply chain include natural disasters and extreme weather events, wars, and technological disruptions. While many supply chain managers have focused on making operations resilient, it's difficult to completely avoid interruptions when handling the flow of goods and raw materials.

This makes innovation and automation critical to today's successful supply chains.

Innovation and Automation Are Essential to Surviving Supply Interruptions

Supply chain management has always been a balancing act-monitoring changing conditions and preparing to quickly pivot depending on changing circumstances. Amidst continued disruptions, continuous innovation is essential. Innovation and automation can help your company improve supply chain performance and meet the expectations of your customers and other stakeholders.

Here are five best practices to reduce disruptions and keep your supply chain working smoothly.

1) Embrace Digital Transformation in Supply Chain Management

Paper logs and even spreadsheets are not conducive to modern supply chain management, but digital transformation can be a painstaking process. The common response "we've always done it this way" can severely hinder your workforce's adoption of digital culture. In reality though, you need the power of AI and automation to build a truly resilient supply chain.

It's also essential to invest in technology so your teams have the tools they need for data sharing and analysis. For example, with modern tools, your company can leverage proprietary data to gain insights and identify areas of improvement. Additionally, you can harness big data to obtain visibility into economic and industry trends so your company remains one step ahead.

Furthermore, cybersecurity should be an integral aspect of your digital transformation, ensuring your supply chains remain secure. Security involves not only firewalls and data privacy protocols, but training staff to recognize risks and follow proper procedures to keep sensitive data safe.

2) Enlist Vendors as Collaborators

Supply chain innovation doesn't happen in a silo. Vendors that provide crucial goods and services to your supply chain can also give you valuable insights and data if you treat them as respectable collaborators. The information flow must be two-way though, so be prepared to share data with your collaborators. Excellent cybersecurity is vital for this information flow to minimize third-party risks, such as a hacker infiltrating a vendor that then breaches your ecosystem.

Collaboration leads to better problem-solving because you bring the practical knowledge of the operator or supplier to the table. Establish regular and open lines of communication with your partners to share information and collaborate on critical issues.

Transparency will help build trust with your supply chain collaborators, strengthening relationships and fostering partnerships. When your strategies align, seek out common goals and objectives to create a sense of shared purpose. You might even consider a joint investment in new technology if the innovation benefits both parties.

3) Use Digital Supply Chain Twins to Drive Intelligent Decision Making

One of the breakthrough technologies in recent years that is transforming supply chain operations is digital twins. Digital supply chain twins are replicas of your company's physical supply chain operations in a digital space. Twins help you make better decisions by putting real-time, detailed information about the entire supply chain at your fingertips, in an easily digestible format.

When you apply this cutting-edge technology to your supply chain, you will:

Optimize Operations: Gain insights into the functioning of each segment of your supply chain to identify bottlenecks, inefficiencies, and underperforming elements.

Improve Visibility: A digital supply chain twin can provide real-time visibility along the entirety of your supply chain, from inventory levels to customer deliveries, and even manufacturing lead times. Visibility allows you to be proactive in dealing with glitches before they become severe disruptions that can take a bite out of your revenue.

Demand Forecasting: Seamless supply chain management requires more than monitoring real-time operations. Digital twins can help you model the future for more accurate forecasting and demand planning.

4) Add Agility to Warehousing and Inventory Management

Over the past few years, supply chain disruptions led many companies to switch from just-in-time inventory management to just-in-case. However, the JIC model caused an oversupply of consumer goods as seasons changed and demands shifted. Therefore, a more agile approach toward warehousing and inventory management is essential to innovative supply chain operations.

For example, in a fulfillment warehouse, new technologies can reduce order cycle time. This is done by analyzing order data to optimize layouts and reduce picking times. Robotics can improve warehousing processes, aid human workers, take over repetitive tasks, and increase overall efficiency.

With inventory management, companies can leverage data from economic trends forecasts and sales history to establish reorder and safety stock levels that meet demand without creating excess stock. Active and agile inventory management keeps stock counts accurate, prevents over-and-under ordering, and recalibrates supply chains based on current manufacturing cycle times.

You can innovate in your warehouse with simple and widely available technologies. For example, RFID and barcode scanning can improve inventory management, increase accuracy in order picking, and give real-time visibility into the location and amount of each SKU in stock.

A digital transformation inside the warehouse is a terrific way to reduce overhead, increase the speed of warehouse operations, and enhance accuracy.

5) Never Rest on Our Laurels

Continuous innovation may be the most critical element for supply chain resilience. Once you've achieved digital transformation, you can't afford to rest on your laurels. Technology and supply chains are constantly evolving.

You have a continuous stream of data from your operations, so implement processes that provide consistent data analysis and reporting. You don't want to wait till the end of the quarter or the end of the month to discover that a freight partner isn't delivering on time, or a raw materials supplier isn't meeting your quality standards.

Build a culture of innovation by rewarding your employees for developing creative solutions to supply chain challenges. Lastly, ensure that their skills remain sharp by providing ongoing training that firmly roots your culture of digital transformation.

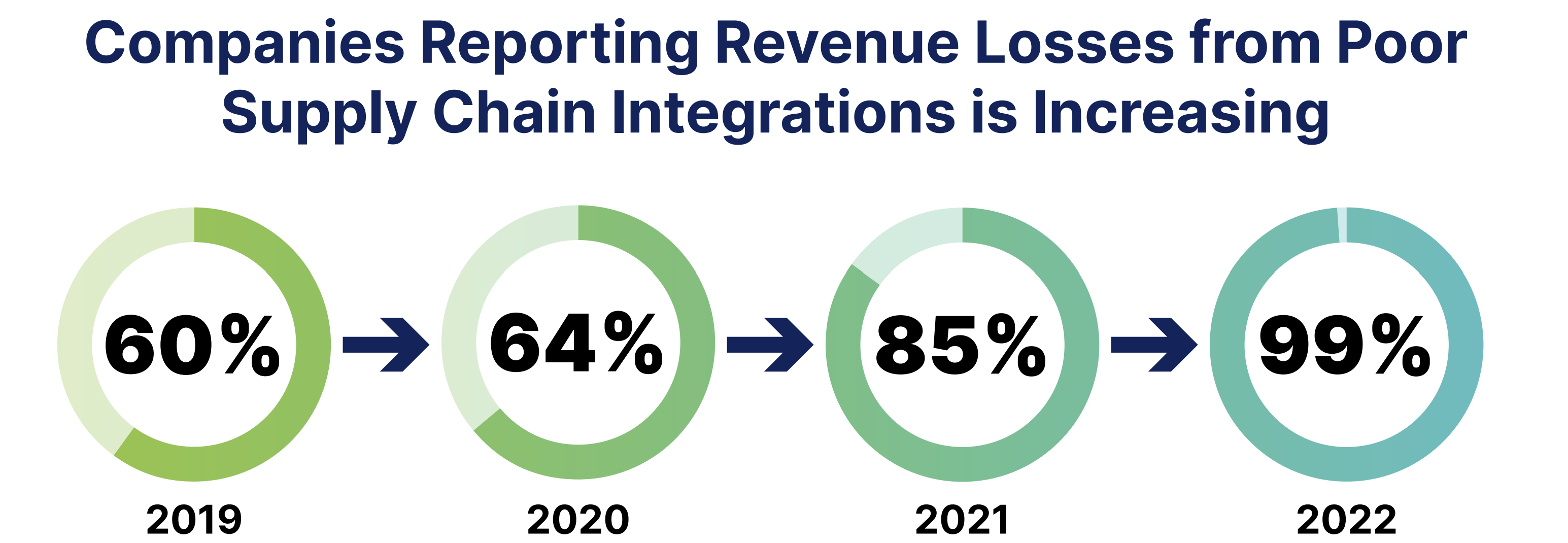

The Actual Cost of Supply Chain Innovation

If you find yourself wincing when thinking about the resources you need to invest in modernizing your supply chain, consider the flip side, the cost of failing to innovate. While new technologies and staff training require an upfront investment, digital transformation allows you to automate many routine functions. This saves time, enabling your team to perform higher-level functions and analysis rather than toiling to complete menial tasks. Having performance information in real-time allows you to make swift decisions, saving your company from costly and time-consuming supply chain disruptions.

Innovate With Cleo

Whether you are integrating your WMS and EDI solution, automating EDI & API transactions, or enhancing manual processes, without the right integration technology in place, tackling these challenges can be tedious.

Cleo's leading innovation in the ecosystem integration sector is transforming the way businesses communicate and achieve supply chain efficiency. With Cleo, you can expect increased supply chain control, automation, and visibility, through integration. Cleo understands the volatility of supply chains, especially in the current climate, and how supply chain continuity is integral towards a company's success.

Watch How EDI Creates Supply Chain Efficiency

Watch How EDI Creates Supply Chain Efficiency

For businesses looking to keep their critical business processes current, gain control and advance their supply chain efficiency, partnering with Cleo can provide your business with the governance and capabilities to increase efficiency in any business relationship.

Jake Rheude is the Vice President of Marketing for Red Stag Fulfillment, an eCommerce fulfillment warehouse that was born out of eCommerce. He has years of experience in eCommerce and business development. In his free time, Jake enjoys reading about business and sharing his own experience with others.

About Cleo