14 Supply Chain Trends for 2024

Over the past few years, supply chains experienced significant disruptions around the globe in nearly every industry. These disruptions provoked companies to evolve their supply chain operations and processes to maintain business continuity to the best of their abilities. This evolution led Cleo to identify and analyze a handful of supply chain trends that we expect will dominate 2024. Continue reading to learn about 14 supply chain trends for 2024 and beyond.

14 Supply Chain Trends To Know For 2024:

1. Supply Chain Disruptions and Delays Are Normalized

2. Increasing B2C and B2B Commerce

3. Rising Supply Chain and Logistics Costs

4. Supply Chain Integration Complexity Causing Greater Losses

5. Sustainability Continues to Triumph

6. Continued Micro-fulfillment Strategies in the Last Mile

7. Lack of Supply Chain Visibility and Analytics

8. Real-time Supply Chain Agility and Flexibility

9. Investments in Supply Chain Integration

10. Automated Supply Chain Technology

11. Investment in the Customer Experience

12. Air Shipping is on the rise

13. Trade Digitalization is a Multi-billion dollar industry

14. Seeking Supply Chain Future-Proofing Strategy

1) Supply Chain Disruptions and Delays Are Normalized

At first, supply chain disruptions induced by the pandemic, unavoidable weather, or other circumstances, caused massive backlash and widespread anger amongst consumers and businesses alike. Especially in markets such as the U.S. where consumers and businesses have been conditioned to expect to receive any product they want, from anywhere in the world, in only a few days after ordering. Furthermore, when consumers would walk into stores, whether retail, grocery, big-box retailers, etc., they were often surprised (and angry) to find shelves empty and products sold out.

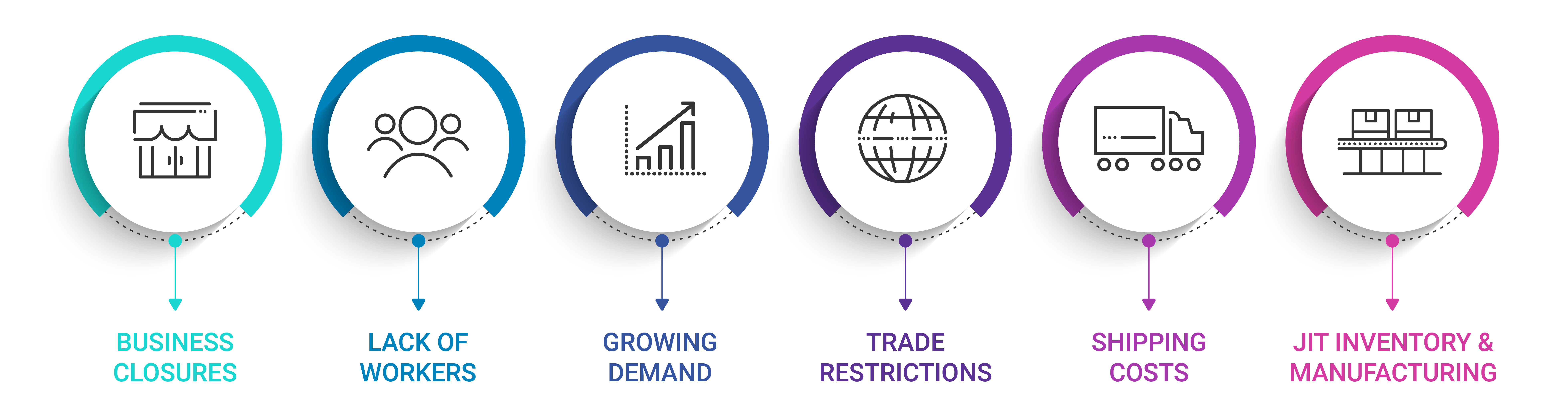

However, over time consumers have learned that the majority of supply chain disruptions and delays are out of the control of businesses and have become more accustomed to not receiving products and goods on demand. Some of the reasons for these delays include:

● Business closures in various industries such as manufacturing, logistics, and retail

● Lack of workers

● Growing demand

● Trade restrictions

● Increased shipping costs

● Just-in-Time (JIT) inventory and manufacturing management

Looking at the above list, the reasons for most of the delays are outside of a business's control, except for JIT. JIT became a popular method of inventory and manufacturing management where companies work closely with suppliers to only receive goods as soon as they are needed.

The reason for the growth in popularity is because this method increases profitability since there is always minimal inventory on hand. Therefore, businesses reduce the amount of unused inventory, increase operational efficiencies, can source locally, and can work out of smaller warehouses (lower rent and fewer employees needed). However, JIT has since become a major reason why supply chain disruptions are occurring globally, forcing companies to reconsider this approach after seeing the significant delays it caused.

It will be interesting to see if the supply chain will ever bounce back to the expedient and highly efficient process it once was, or if consumers and businesses will adapt and normalize a slower supply chain moving forward.

2) Increasing B2C and B2B Commerce

Consumers and businesses are buying more goods and services than ever before. This is due to a multitude of reasons, including:

Greater Income and Discretionary Spending

Over the past few years, employees have seen rising wages that are largely due to talent wars. This has led to workers having more discretionary spending. However, with inflation rising at astronomical rates, purchasing power is starting to decline so this will be something to keep an eye on.

Additionally, companies have been experiencing tremendous growth, with some performing the best they ever have during the pandemic. To keep these companies afloat and advancing, they need more products and services to scale their business operations.

More Products and Services Available

The sheer number of products, services, and businesses is increasing. As the internet and new technologies make it easier for anyone to start their own business, consumers and businesses have more options for what to buy and who to buy it from.

New Financing Options

Particularly in the realm of B2C, consumers are being presented with a slew of financing and payment plan options. This makes it easier for consumers to buy products even if they do not have the money to pay for them right now. Examples of retailers that offer buy now pay later plans include QVC, Amazon, and Walmart, among many others.

Investment Opportunities

When it comes to B2B commerce, companies are realizing the value of investing in cutting-edge technology to improve and optimize their supply chains and operational efficiencies. This is especially true with talks of a potential, looming recession hitting the U.S. and global economy in 2024. It is well known that companies that invest in technology and their business during periods of economic downturn are poised to make the largest growth once the recession starts to lift. This is because the businesses that invest in themselves acquire the infrastructure to scale, allowing them to surpass competitors and steal market share.

More Consumers

The world's population is now about 8 billion and growing. With more people comes more potential buyers. This is great news for companies since they can sell more products and services. Additionally, consumers are becoming younger, as Gen Z now has a combined buying power of $360 billion and continues to grow.

Continuous Technological and Product Advancements

With technology improving daily, products and services regularly receive updates. Therefore, companies and consumers always have new versions of pre-existing products and services they can upgrade to, as well as entirely new products and services to buy for the first time. Simply put, innovation moves markets and drives supply chain activity.

eCommerce

eCommerce has seen an upwards trajectory since the 1990s when the likes of Amazon, Alibaba, and PayPal debuted. This upwards trend dramatically increased in the 2000s, and 2010s as more companies began building online stores, household computers and personal laptops became standard, and smartphones became widespread. Now consumers can shop from anywhere in the world, at any time of day, with only a few clicks.

Ease of Buying and Selling

The overall ease of buying and selling products digitally has become easier due to a combination of a few of the reasons we covered. This includes a mixture of eCommerce, financing options, and greater discretionary spending. These reasons make shopping accessible and quick for consumers to buy without even thinking.

3) Rising Logistics Costs

Companies across every industry and country are hurting from rising logistics costs, which are being driven by higher fuel and labor costs resulting from uncertain market direction. With the demand for logistics services growing, and the supply of workers shrinking, companies are being forced to spend more to move products and raw materials to their intended locations.

In order to combat these rising logistics prices and maintain a positive bottom line, some companies are passing rising logistics costs onto consumers and businesses. This is done by increasing product prices.

Unsurprisingly, consumers are upset as they are now paying more money for the same product, or worse, spending the same amount on the product but receiving less of it. The latter is known as "shrinkflation." For example, a carton of ice cream that was $4 for two quarts worth is now $4 for 1.5 quarts of ice cream. Shrinkflation may go unnoticed by consumers as it is not in a company's best interest to advertise the downsize.

There is also the issue of seaport bottlenecks. This is a result of companies ordering more products because they experienced an increase in demand, especially during the pandemic when the stimulus checks hit consumers' bank accounts. However, this increase in demand resulted in a monumental swell of exports and imports, causing massive wait times at bustling and critical locations, such as Long Beach or the Port of Los Angeles. Accordingly, there are stories of boats being docked outside of ports for months waiting to be unloaded.

While these boats are waiting to be unloaded, it means they cannot move on to transporting and delivering the next shipment. Therefore, this also drives up demand while decreasing the supply, further exacerbating the problem.

Companies are then forced to decide if they are willing to pay a premium to get products into the hands of consumers, or if they should wait until prices drop. The issue with paying a premium is it eats into a company's bottom line unless they pass the additional costs onto the consumer or find a way to cut costs in a different area. Waiting for the prices to drop is also not an ideal option as logistics prices are at an all-time high and continue to rise.

4) Supply Chain Integration Complexities Causing Greater Losses

Supply chain integration is a great way to increase efficiencies and boost revenue. However, integration complexities and issues can just as easily corrode revenue. In fact, according to a 2021 survey, 31% of respondents revealed their companies lost more than $250 thousand in 2020 due to poor integrations — up from 25% in 2019. Furthermore, 10% of respondents claimed their companies experienced more than $1 million in lost revenue in 2020 alone.

We outline three reasons why supply chain integration complexities are stealing revenue below.

Integration Gaps

As one of the primary reasons for revenue loss, integration gaps refer to areas of the supply chain that are not integrated (connected) but could be. This can occur for several reasons, including:

● Legacy technology

● Limited integration features and compatibility

● Lack of knowledge, resources, and/or bandwidth to conduct integrations

● Relying on humans to perform actions that could be automated through integration

● Utilizing managed services which keep companies in the dark, therefore causing them to be unaware of integration gaps

Lack of End-to-End Visibility

End-to-end visibility gives companies control by allowing them to better prepare for a variety of circumstances, collect pivotal data, optimize supply chains, and become knowledgeable on the inner workings of their businesses.

Lack of end-to-end visibility can steal revenue in a few different ways. Without visibility, companies cannot collect in-depth data that can help guide strategic decision-making. Additionally, companies cannot optimize their supply chains and processes if they do not have insight into what areas need improvement. Lastly, without visibility, errors may go unnoticed. This makes businesses less agile as they cannot adapt as quickly to disruptions in the supply chain because they are not informed of issues until it is too late.

Legacy Technology

Legacy technology is detrimental to revenue for numerous reasons. These include:

Lack of Flexibility and Scalability

If a platform cannot scale when a company is experiencing growth, the business will be missing out on revenue. This hurts revenue because companies will have to turn down business opportunities because they cannot accommodate the demand they are receiving.

System Downtime

System downtime equates to fewer time companies can fulfill business requests. Additionally, downtime causes a company's employees to have to spend valuable time fixing errors, rather than focusing on other pressing projects and tasks. Lastly, system downtime may cause a company to lose trading partners because trading partners may view the company as unreliable.

No Visibility

Visibility helps companies make more money because they can better optimize their supply chains and processes. More efficient supply chains and processes mean less time and money is being spent on creating a product or service, thus improving a company's bottom line.

Outdated Features

Outdated technology relies on outdated capabilities. Outdated capabilities are not as efficient, intuitive, or beneficial as newer capabilities. Newer technology can improve processes and provide greater insight into a company's supply chains and processes.

Poor Cybersecurity

Older technology is frequently much more vulnerable for cybercriminals to hack and infiltrate. On average, companies lose nearly $4 million for a single data breach. With cyberattacks on the rise, legacy technology is a huge liability for companies.

5) Sustainability Continues to Triumph

Companies around the world are prioritizing sustainable products, solutions, and services, especially when it comes to manufacturing, logistics, retail, and supply chains. Consumers and trading partners are increasingly supporting companies that incorporate environmentally friendly practices into their businesses. Therefore, companies should accommodate these demands if they want to win more business and create happier customers.

Companies can incorporate sustainable practices into their business operations and supply chains through a variety of methods and technology, including:

● Using more sustainable packaging materials

● Utilizing greener vehicles and cleaner fuels for transportation

● Harnessing renewable energy sources

Another key sustainable practice that is growing enormously in popularity is last-mile logistics. This effort utilizes local fulfillment centers to ship products to consumers already in the area. This is a greener approach compared to alternative shipping methods because it reduces fuel consumption, requires a smaller vehicular fleet, consolidates shipments, and designs fuel-efficient delivery routes.

Businesses do not have to include all these efforts in their operations but can select the methods that make the most sense for their business and will create the largest positive impact. So not only will incorporating more sustainable and environmentally friendly practices improve a company's bottom line by increasing consumer demand and creating more business opportunities, but it will also help companies create a smaller environmental footprint — creating a healthier world.

6) Continued Micro-fulfillment Strategies in the Last Mile

As we started to mention in the previous trend, last-mile logistics is the last step in the delivery process where the product/order is transported from a distribution center to the recipient. However, the name can be deceptive as last mile logistics can refer to anywhere from a couple of hundred yards to 100 miles.

As eCommerce continues to explode in popularity, micro-fulfillment is rising enormously to carry out each of these individual orders faster. Micro-fulfillment can look like a retailer offering consumers an option to buy online and have it delivered from the store, or buy online and pick up the order in-store.

With micro-fulfillment growing, companies are continuously looking for new ways to improve last-mile logistics to make them more efficient and environmentally friendly. To do this, businesses are harnessing the power of technology.

Some of the ways technology can improve last-mile logistics are by:

● Mapping out the most environmentally friendly delivery routes

● Reducing repeat delivery attempts and thus minimizing CO2 emissions by providing recipients delivery time updates—allowing recipients to notify delivery drivers if they will not be able to sign for the package

● Collecting data on deliveries, routes, emissions, fuel consumption, etc., which can be used to better optimize future deliveries

So not only are companies creating a smaller environmental footprint with micro-fulfillment optimization, but they are also able to save money by reducing costs and improving efficiencies. Lastly, consumers benefit from micro-fulfillment because they often receive packages quicker than alternative processes, along with having more delivery options to pick from.

7) Lack of Supply Chain Visibility and Analytics

Visibility is essential as it gives companies control over their businesses. Without visibility, companies will not possess an in-depth understanding of their own operations. In particular, a major tangible benefit of visibility is the ability to collect data and analytics.

In the digital era, data has become king as companies rely on data to:

● Identify weak areas in their supply chains and processes

● Optimize processes and supply chains

● Determine what is working and what is not

● Create a source of truth that can be referenced when needed (Top 5 Supply Chain KPIs)

To collect data and harness analytics, companies can adopt cloud-based integration technology. Integration technology will connect a company's various platforms and systems in a supply chain to create a single source of truth. Additionally, all data is automatically updated in real-time so companies can be sure that they are analyzing the most up-to-date and accurate information available.

However, many companies have yet to incorporate integration technology for data collection purposes. Some companies simply do not collect as much data as they should, while others rely on humans to pull the data manually. Manually pulling data is time-consuming, as it requires humans to hop from platform to platform to find the information they are looking for. Additionally, humans are error-prone and can easily mistype, record data in the wrong fields, or read statistics wrong. Lastly, by the time a human collects all the data they are searching for, the data will likely be outdated, thus the company will be analyzing and basing decisions on inaccurate information. For all these reasons, cloud-based integration technology offers a much brighter alternative.

8) Real-Time Supply Chain Agility and Flexibility

Business moves faster than ever. Accordingly, companies need to remain agile. One way companies can do this is by setting up real-time supply chain updates. Updates can be used both internally and externally to keep all parties informed.

Internally, companies can use supply chain updates so team members are constantly informed of the performance and happenings within a particular supply chain. This can be extremely useful in the case of delays, disruptions, and errors, as companies can immediately hop into fixing any issues before any significant impact is felt in a supply chain.

Externally, companies can alert customers and trading partners of any delays as soon as they occur, giving maximum advanced notice of any disruptions. Supply chain updates can also help notify customers and trading partners of order and shipment updates, such as when a product leaves the warehouse and the expected delivery time.

Consumers and trading partners alike have come to expect real-time updates regarding their orders. Companies need to meet this demand if they want to garner new customers and keep existing ones, as more companies are providing them.

9) Investments in Supply Chain Integration

Supply chain agility allows companies to quickly adapt their strategies and processes to meet evolving supply chain market expectations and customer demands. Since supply chain requirements change very fast, companies are looking to invest in technology that can help them stay nimble.

The benefits of supply chain agility include easily adapting to supply chain requirements, staying competitive, fulfilling customer demands, and quickly adjusting to unplanned setbacks.

Moreso, supply chain agility helps companies improve overall business continuity. Business continuity is becoming increasingly vital as companies across the globe experienced major interruptions and instability during the COVID-19 pandemic, and the impact is still being felt today. Ramifications include bottlenecked ports and empty store shelves where companies are not able to meet consumer demand and are losing out on business.

Not only do interruptions in business continuity negatively impact the a business "today,", but it also impacts them moving forward. This is because brand loyalty is fleeting; if consumers cannot access the products and services they get from their usual brand or supplier, they will likely find the products and services elsewhere. Therefore, consumers may continue using the new brand or supplier moving forward. Thus the business that experienced business continuity interruptions may never regain those customers, even after its supply chain is running normally again.

10) Business Investments in Automated Supply Chain Technology

With business moving quicker than ever, companies need to expedite their supply chain processes. One of the most common solutions is to implement automation. Automation utilizes modern technology to automate manual tasks, replacing the need for human intervention and instead relying on technology to complete tasks.

Automation is used in nearly every industry since it produces impactful results quickly, from logistics and manufacturing to retail and food and beverage. The main benefits of supply chain automation include:

Lower Operating Costs

There is an upfront cost associated with automation as new technology needs to be bought, set up, and deployed. However, the costs are quickly recouped because companies no longer have to pay humans to perform the tasks.

Improved Efficiencies

Automation works incredibly fast and is highly responsive as it is always on standby requests. Additionally, automation does not require breaks, nor does it take nights, weekends, and holidays off like its human counterparts.

Reduction in Errors

Humans are naturally error-prone, as they can easily mistype, record data in the wrong fields, read statistics wrong, send emails to the wrong recipients, etc. Since automation harnesses advanced technologies to perform tasks, errors are minimized.

Lightens Employee Workload

With automation tackling tasks that humans were responsible for, team members can now focus their time and energy on other pressing projects. Therefore increasing productivity and relieving workers of mundane, repetitive tasks.

Not only does it benefit the company that implements automation, but it also positively impacts its trading partners and customers. Trading partners and customers benefit from quicker and more accurate response times, allowing businesses to move faster and get products into the hands of consumers faster. This creates stronger and more positive relationships between all parties involved.

11) Investing in the Customer Experience

Especially with eCommerce and online shopping taking off, customers have more options than ever before when it comes to selecting which company to buy a product or service from. To differentiate themselves, companies are investing in the customer experience to make the buying process easier, faster, and more enjoyable for consumers. The hope is that customers will share their positive experience through word of mouth, as well as will convert into repeat customers.

One way to determine how to improve the customer experience is through surveys. Companies can ask customers to complete a survey after a purchase, demo, discovery call, etc., where they are asked about their experience. The company can then analyze the survey results to find common threads, patterns, and experiences customers are dissatisfied with. Thus, the company can pinpoint areas of weakness that they can then focus on refining to improve the customer experience moving forward.

Not only will addressing these areas of weakness improve customer satisfaction, but it will also likely improve the supply chain. This is because problematic areas for external parties are also likely problematic areas internally as well, so fixing the issue becomes a win-win.

Other ways to invest in the customer experience include:

● Quicker customer service response times

● Supplying more informational resources

● Providing trainings or instructions

● Improving website accessibility, ease of use, and design

● Offering more product and service options

While it is not necessary to invest in all the above areas, companies can consider which ones will have the largest impact on their customers.

12) Air Shipping on the Rise

The most common modes of freight shipping are ground (trucks) and marine (boats), however, there is another option that is quickly gaining popularity. This method of shipping is air (planes).

While air shipping has been around for years, it was not until recently that it has seen a large uptick in interest. This is largely due to the falling price of shipping via air that occurred in wake of the COVID-19 pandemic. The reason is that marine shipping became much more expensive as ports have become clogged with ships, which has increased marine demand and decreased the supply of ships.

Other than its continued affordability, other benefits of air shipping, include:

Gentle

Air shipping is gentle on the goods being shipped, making it perfect for fragile and expensive items like technology, glassware, and musical instruments.

Shipping Times

Air is by far the fastest shipping method as it can cover the most ground in the shortest amount of time.

Reliability

Airports run on strict schedules. Therefore, planes have to take off at designated times. Additionally, planes do not have to worry about running into unforeseen traffic like ground shipments.

Order Tracking

Airplanes are easy to track since they are regulated and given departure and arrival times. Therefore, tracking a package is as easy as knowing which plane the package is on. Compare that to ground and marine shipping where there is no set departure and arrival time, as there are too many factors to consider.

Deliver Anywhere

Airplanes can deliver products nearly anywhere in the world, as they are not limited by ocean ports and coastlines like marine shipping, nor do they require roads like ground shipping.

Security

Airports have strict security measures in place, making it much harder for packages to be stolen.

13) Trade Digitalization is a Multibillion Dollar Industry

Digital trade is where goods and services are either bought digitally or delivered digitally. The practice is increasing in popularity due to high (and getting higher) global internet accessibility and the astronomical demand for eCommerce. Trade digitalization produces new business opportunities, allows businesses to reach more consumers, creates more resilient supply chains, and reduces transaction costs. A major reason for these benefits is that trade digitalization makes it much easier for buyers and sellers to connect compared to traditional methods.

One of the key aspects of trade digitalization is that it has allowed for widespread international business. Consumers can now place an online order with a company based halfway around the world, and receive the product instantaneously on their internet-connected device or have it delivered to their doorstep in a few days. This gives consumers more options to pick from when shopping.

On the business side, companies are no longer tethered to only selling to consumers that live within proximity to one of their physical stores or live within the same country. Companies can sell to virtually anyone as long as the consumer has internet access and uses an accepted form of payment. Therefore, companies are tapping into entirely new markets that were previously unavailable.

Companies of all sizes are realizing the massive value of trade digitalization and are investing in the infrastructure to participate. Investments can look like integration technology, EDI and/or MFT software, automation, and multi-language websites. These investments help businesses' supply chains scale, improve efficiencies, reduce complexities, compile accurate data, and more.

14) Seeking a Supply Chain Future-Proofing Strategy

Looking ahead, an overarching theme of supply chain management is to create business continuity even through unexpected events. This is a challenge because companies have to prepare for unforeseen circumstances.

One solution is for companies to create contingency plans for a wide range of scenarios. Therefore, if an event does occur that impacts the supply chain, companies are prepared with solutions that can rapidly address the problem at hand, helping curb the impact of the disruption.

For example, most companies were not prepared for a global pandemic, hence why the entire world experienced massive supply chain disruptions. If companies had created contingency plans for a pandemic, the disruptions could have been far less intense and may not have lasted as long.

Companies should consider creating contingency plans for cyberattacks, extreme weather, labor shortages, pandemics, and more.

Along with business continuity, companies can also future-proof their supply chains by upgrading their legacy technology. By harnessing cutting-edge technology, companies can ensure they are as competitive as possible since tech can offer efficiency, reduced costs, improved communication, new features and capabilities, data and insights, and more.

Companies that do not invest in technology tend to quickly fall behind competitors as outdated technology cannot keep up with newer advancements. Additionally, once market share is lost, it becomes difficult to recover because not only is the laggard company falling behind, but its competitors are simultaneously pulling ahead.

Companies that cling to legacy and outdated technologies then have to spend time and resources researching, vetting, implementing, learning, and deploying technology solutions which can take months and years to fully complete. This makes it very challenging for companies to gain back lost ground.

Real Stories of Supply Chain Agility

Cleo Can Help Automate your Supply Chain

With business and supply chain operations evolving daily, companies need to implement solutions that keep them running at peak performance to remain competitive. One way to do this is by improving, optimizing, and future-proofing your supply chains with cutting-edge ecosystem integration technology. Luckily, Cleo is the pioneer and global expert in the space.

Our flagship product, Cleo Integration Cloud (CIC) is used by thousands of companies around the world on a daily basis, allowing them to operate quickly, smoothly, and effectively. CIC has numerous benefits and features, including automation.

With CIC, companies can harness the power of integration automation to:

● Respond instantly to trading partners

● Translate EDI file formats

● React quickly to unforeseen problems

● Collect real-time data from integrated systems

● Lower operating costs

● Improve overall efficiency

● Lighten employee workload

● Increase competitiveness

● Elevate order accuracy

To learn more about automation and how Cleo's cloud-based B2B ecosystem integration platform and strategic services can optimize your business's supply chains, check out our helpful and informative resource library. To contact us, email us at sales@cleo.com or call us at +1.815.282.7695 to start a conversation with one of our EDI experts.

About Cleo