Real Stories of Supply Chain Agility – Part Six

Every day, on calls with Cleo customers, I am learning first-hand how leading supply chain-driven businesses are adjusting to the COVID-19 pandemic. In this blog series I share insights about how companies in various industries are responding. Their agility is remarkable, and something we can all learn from. Hope this helps everyone think differently.

Blog #6 – Apparel Industry

As I continue to speak with our customers about how they’re combating this global pandemic, the biggest takeaway I’ve had is just how creative companies have been. Each story is seemingly more fascinating than the last, as companies find ways to handle supply chain disruption. Cleo collaborates with our customers on what strategies they are adopting to manage the challenges unleashed by COVID-19.

As the saying goes, “Necessity is the mother of all invention.” The best companies are those that are focused now on improving or replacing their prior business models as they anticipate recovery after the crisis. The following is an excellent example of creativity and innovation in the face of adversity.

While the apparel industry has been significantly impacted by COVID-19, it is heart-warming to witness first-hand how one of our apparel industry customers is transforming its business model to leapfrog the competition.

Company Background

First, a little background about this company before we dive into its intriguing experiences. The company designs and manufacturers apparel with licenses for major brands, including Warner Bros., Sony, and Disney. Additionally, the company possesses a large portfolio of licensed brands to serve as a one-stop shop for retailers across all different product lines.

Until recently, our customer utilized traditional EDI to manage transactions with retailers. But now, as retailers are seeing little to no foot traffic due to the global pandemic, they are preferring to instead sell merchandise on their company web stores. Retailers are also desiring to benefit from drop-ship models that reduce the cost of inventory and fulfillment, but until recently needed to carry the inventory to fulfill demand.

Drop-ship models reduces inventory through consolidation at its distribution center.. Essentially, the retailer sells goods on its website, and the company manufacturers and ships to the consumer directly, and the retailer pays the company its price. This is hugely beneficial for the retailer because it doesn’t have to carry any inventory, and the company because it makes it invaluable to retailers who will collaborate more closely to save inventory carrying costs.

What are the Challenges?

Declining foot traffic in retailer’s physical stores has greatly impacted apparel sales – that’s the primary concern thus far. The impact that COVID-19 has had on the economy has quite frankly softened the demand for apparel, because it’s a discretionary spend. There has also been an increasing desire from retailers to sell and fulfill online, which traditional EDI-based order-to-cash processes simply cannot adequately support. There’s also the fact that retailers are unhappy with inventory investment/fulfillment cost and the lack of demand visibility due to the evolving nature of the pandemic.

Innovation

Our customer’s company has selectively developed an ecosystem of partners who can support a make-on-demand business model, where, in exchange for collaborating on forecasts, its manufacturing partners will make the requested product and directly ship it to the consumer without our client holding inventory or carrying fulfillment costs.

What it decided to do was evangelize the make-on-demand business model. But how? Think of what happens when a consumer’s order is submitted via a retailer’s website or online company store (or a marketplace, such as Amazon). If the order for the requested item goes straight to the manufacturer, then it can be made and fulfilled on demand.

Retailers gain a win-win because they can now depend on the manufacturing company to bolster their e-commerce strategy, drive revenue uplift, and reduce inventory and fulfillment costs. This creates a shared model of collaboration where the retailers and the manufacturer can both achieve increased revenue and improved margins.

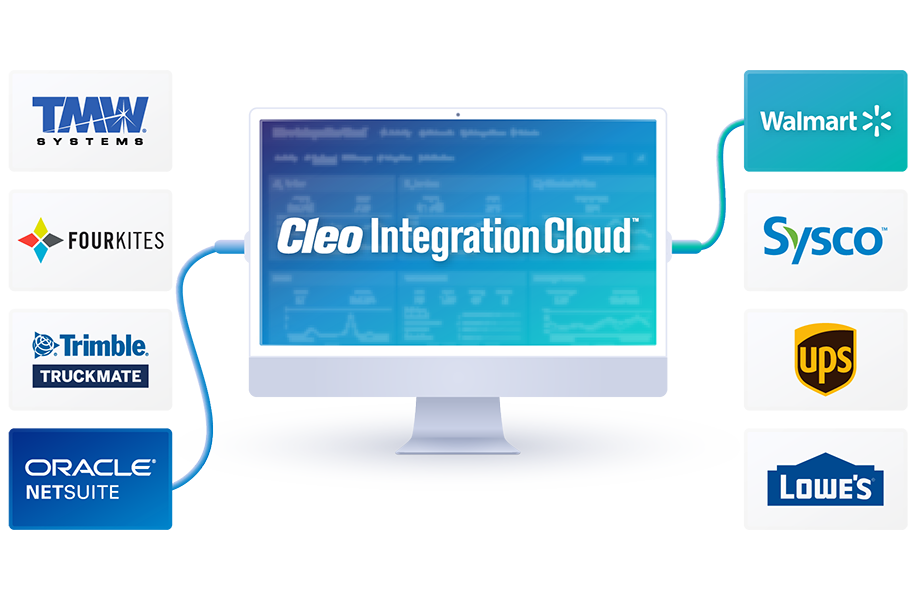

Further, the make-on-demand model also allows for deeper collaboration between our customer and its partners on forecasting, promotions management, and replenishment planning across the retailer and the company actually making the goods. With an ecosystem integration platform now in place, our customer is able to:

- Build API integrations to the major retailers as well as top marketplaces

- Develop standard provider API operations that will open access to retailers’ web stores

- Enable a real-time order-to-cash process that involves receiving orders, passing them through to its make-on-demand manufacturing partners, and delivering acknowledgments and statuses

- Deliver end-to-end application integration to its back-end ERP systems while decoupling the B2B and application integration flows so that the company can continue to receive and fulfill customer orders even while if their back-end systems is down

One step further, the company invests proactively in a cloud business intelligence platform to:

- Track mandatory royalty attainment

- Provide better forecasts to its license partners

- Deliver performance metrics by product line, location, retailer and& marketplace

- Apply analytics to provide sales insights to retail customers

- Leverage transactional data from the ecosystem integration platform to fuel its Business Intelligence strategy

Where to Next?

With a robust ecosystem integration platform centrally in place, our customer fully expects to see further increases in revenue uplift from greater web store visibility and sales with existing retail customers. It also anticipates a revenue gain from new marketplace enablement that is steadily furthering its outreach and rapidly broadening its business ecosystem. The company will also gain enhanced transactional visibility for real-time order processing and financial reporting, as well as improved customer retention due to 99.95% uptime and cloud stability.

As they say, there’s no time like the present. And this company is using the present economic situation wisely to further its real time, on-demand manufacturing and delivery model.

As always, please reach out to me on LinkedIn with any questions or comments that you might have. And refer to Cleo’s COVID-19 FAQ guide for more suggestions to help you navigate these difficult times.

About Cleo

Watch a Demo

Comprehensive Guide to Gaining B2B Control

Duraflame Case Study