How Disruption Yields Opportunity for Supply Chain Continuity and Agility

Continuity is everything in business. When the unforeseen happens, can you rest easy at night, knowing that you are fully prepared? Or are you unsure whether you’ll be able to conduct business as usual? Whether companies are in manufacturing, logistics, or wholesale, being able to keep business processes running smoothly in the face of unplanned circumstances is something that every organization needs.

Lack of visibility is one of the biggest challenges that companies must overcome, especially when some type of interruption occurs. And while it’s never a good time to deal with those interruptions, the companies that are well-prepared with a continuity plan are the ones who will thrive.

Supply chains must be resilient in the face of unforeseen events. While COVID-19 is truly a once in a century Black Swan event, over the last 18 months, businesses have witnessed first-hand many external events that they’ve also had to manage. From China tariffs and Hurricane Dorian to Saudi oil attacks, supply sources have been impacted to cause short to mid-term supply shocks resulting in lost revenue and profits.

In 2019, for example, the imposition of tariffs on Chinese imports led to manufacturers not receiving supplies in time which caused a ripple effect of not capturing customer demand on time. Suffice it to say, in business, every day is different. And you need the ability to see around corners, and you need a business continuity plan.

What is Supply Chain Continuity?

Supply chain continuity is the state of maintaining durable, reliable, and persistent flows of actions and activities throughout the entire supply chain. Achieving high continuity relies on supply chains becoming agile. It’s sort of a chicken and the egg thing. Supply chain continuity is not something you can buy from a vendor. Companies only gain business continuity through an agile supply chain.

Rather than treating your supply chain as fixed or “static,” forward thinking companies look to identify and qualify alternative supply and demand points that can readily provide them the ability to shift their supply chain participants when unforeseen events impact either supply sources or demand segments.

Ensure your supply chain is dynamic and agile – that is your number one defense against uncertainty. Supply chain agility includes:

- Elasticity with regards to the overall capacity of the chain, the underlying and dependent services, and infrastructure

- The ability to rapidly provision and de-provision partners, suppliers, carriers, and applications in response to supply chain disruption

- 360-degree governance disciplines and mechanisms such as end-to-end visibility, proactive, automated error handling, the monitoring of events and resources, and the measurement and auditing of transactions

Supply and Demand Shocks

When unprecedented and unforeseen events happen, companies might be faced with a lack of supply, but have more demand than ever before. The current global crisis has shut down thousands of Chinese factories over the past few months. But as factories in several Chinese provinces gradually resume operations, the production capacity still averages just 40% prior to where it was before the pandemic.

Some companies with supply chain professionals were able to quickly sense the imminent crisis and ordered supplies from China (as well as Italy) before factories were shut down, thus curbing the impact. Those companies are the fortunate ones; those who were unprepared are now facing supply shortages. This shows the inherent value and need for flexibility and agility inside a supply chain in order to react to supply shocks. End-to-end visibility and the speed to react capabilities are central to success in these ever-evolving times.

The aftermath of this pandemic will also lead to significant demand shocks. While most companies’ discretionary spending will be slowed due to the economic contraction, others will realize gains. For example, the global health crisis is also causing a massive shift to online buying. Those companies that were proactive and had the foresight to build e-commerce channels are doing well, and those that didn’t are struggling (to say the least).

An increasing number of people in the workforce are now working from home for safety purposes and making their purchases online. This is yet another compelling reason for companies to become flexible and agile in the demand chain in order to best work around those demand shocks. The underlying capabilities needed include API-based integration of digital channels as well as enabling process integration for omnichannel fulfillment.

How Do I Gain Supply Chain Continuity?

The only way to get this flexibility and agility throughout your supply chain is through a centralized integration platform. Think about all those local markets today that are running short of toilet paper available for consumers. That’s where having elasticity with regards to capacity is so valuable, because it allows retailers and manufacturers alike to scale up or down as needed. That elasticity provides companies the ability to quickly get another truck on the road with in-demand paper products, because it includes the rapid provisioning and de-provisioning of partners, suppliers, carriers, and applications.

When companies have an agile supply chain, they become proactive instead of reactive. As the world continues to grow more unpredictable seemingly by the minute, businesses need continuity now more than ever. Organizations need to be prepared for anything that comes their way, and supply chain continuity must be a larger part of a company’s disaster recovery plans.

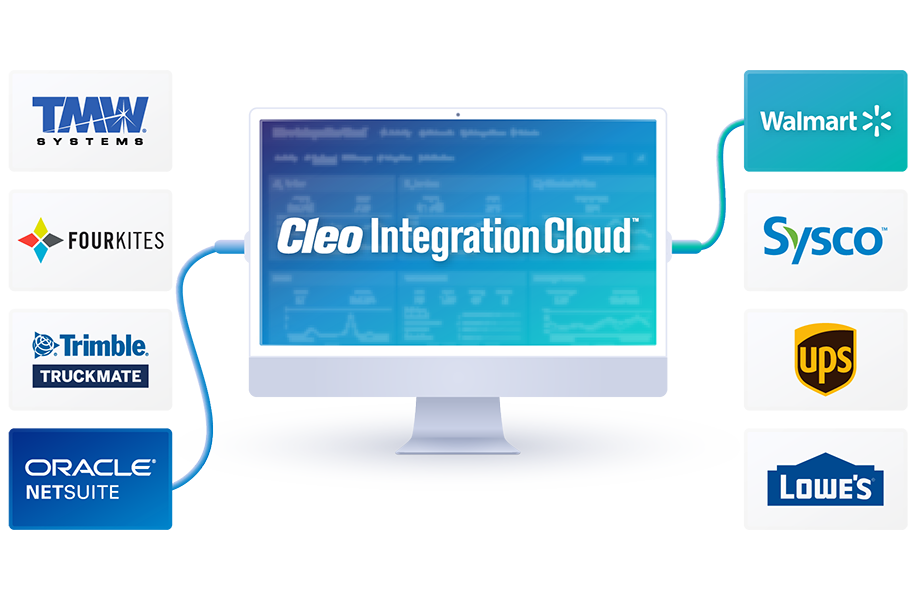

Companies need an ecosystem integration platform that can seamlessly enable integration across business partners and internal applications while orchestrating business processes across various stakeholders in a highly automated manner with business rules and exception management workflows. By managing batch (EDI) and real-time (API) integration flows, companies can facilitate data movement and transformation workflows across cloud and on-premise.

Supply chain continuity enabled by an ecosystem integration platform can:

- Make supply chains resilient by rapidly onboarding new suppliers

- Dynamically respond to demand fluctuations by rapidly onboard customers (including brick and mortar and digital)

- Make decisions based on end-to-end visibility

Retailers have run out of toilet paper not because we lacked the manufacturing in the United States to manufacture huge supplies of it, but because the panic buying signals reached manufacturers only 2-3 weeks after the retailer warehouse inventories were significantly depleted. Those companies with an agile supply chain were already alert because they were proactive and had the infrastructure to make them flexible and scalable.

An agile supply chain eliminates the worry of feeling unprepared because it provides companies with a continuity plan and the flexibility required to overcome any unpredictable events that may come our way. As the current crisis rolls on longer, companies without a dynamic supply chain are forced to become reactive, rather than proactive. With so much uncertainty facing the world around us, don’t allow your business to fall into that same trap.

About Cleo

Watch a Demo

Comprehensive Guide to Gaining B2B Control

Duraflame Case Study