Optimize execution and efficiency

Automate every B2B transaction

Eliminate API and EDI transaction errors

Deliver end-to-end connectivity and visibility

Eliminate chargebacks and missed SLAs

Achieve predictable revenue and profitability

Make ecosystem relationships stronger

Slash onboarding times. Improve revenue velocity.

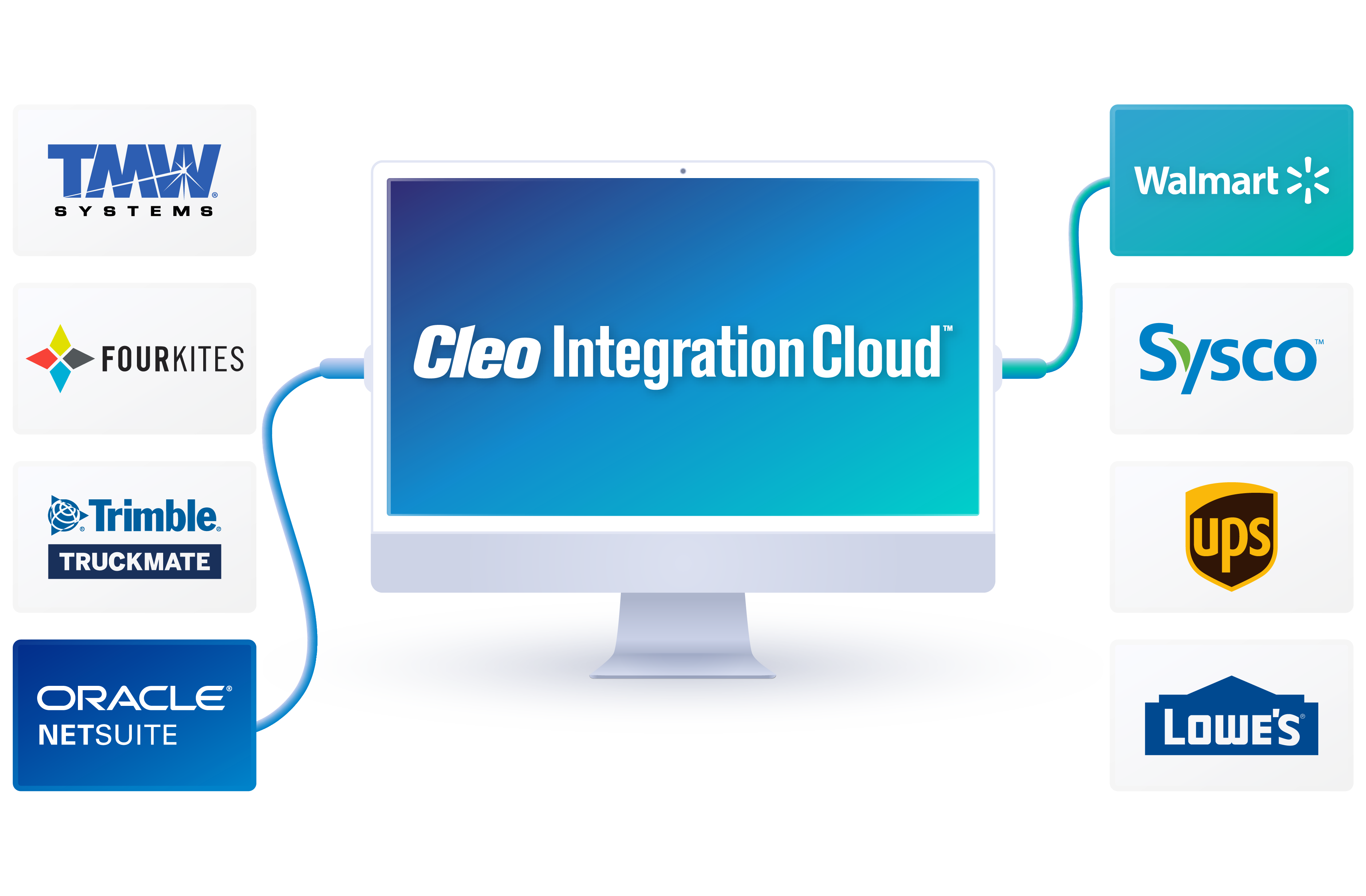

Accelerate go-lives with new trading partners. Leverage pre-built API and EDI integrations to automate supply chain transactions directly into your back-office applications. No coding required.

No more missed transactions. Ever.

Leverage enterprise-level scale and end-to-end integration visibility to ensure every supply chain transaction is received and delivered.

Deliver on your commitments. Strengthen relationships.

Improve trading partner scorecards by eliminating errors and chargebacks through proactive monitoring, alerting and insights.

Control and flexibility. Choose your operational model.

Choose between self-service, managed services, or blended service models to create business agility and outsmart any disruption.

Customer success stories

Discover how Cleo has transformed businesses like yours.

Our customers love Cleo integration Cloud. Learn why.

Read our customer reviews and see why we’ve been rated a G2 Leader for 4 consecutive years.